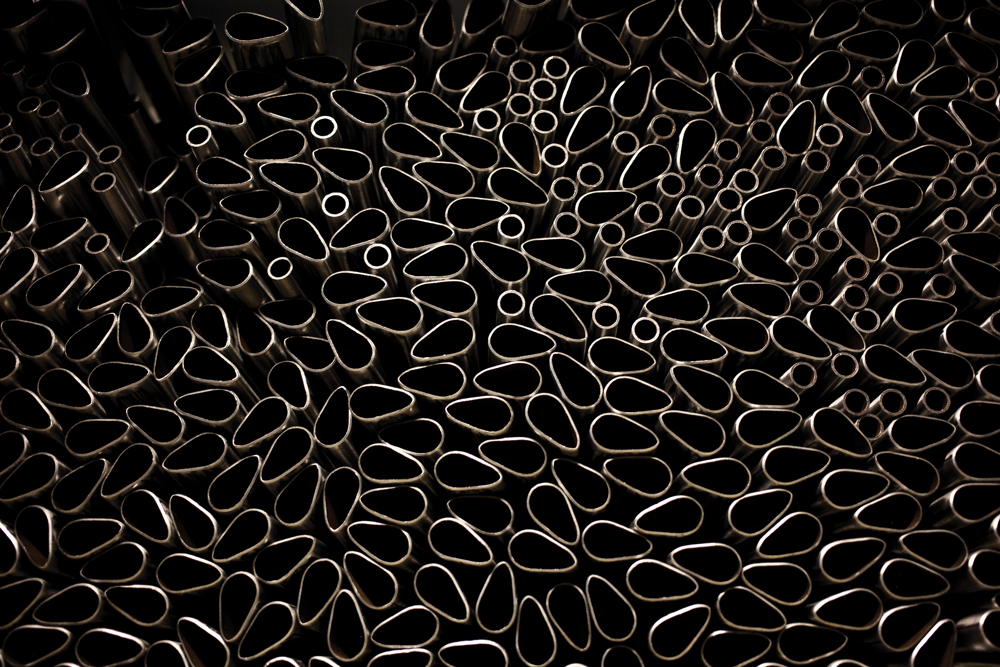

Columbus çelik boruları farklı alaşımlarda ve farklı inceltme oranlarında üretilmektedir. XCR, Omnicrom , Cromoly ve Cromor olarak 4 gruba ayrılmaktadırlar.

Omnicrom

With the introduction of OMNICROM, Columbus ushers forth a new era of steel tubing; unprecedented performance and excellent processing capacity. OMNICROM is the culmination of a long journey. OMNICROM benefits from being enriched with Vanadium combined with a highly controlled production process: the best choice for riders, the best choice for framebuilders.

Mechanical characteristics:

UTS=1300MPa, Ys≥920 MPa, Ap5>15%.

Columbus 25CrMo4

25CrMo4 seamless steel: the chemical composition of this steel, specifying a higher percentage of Chromium, gives to the material good resistance properties to overheating. The formation of carbides prevents the grain enlargement: the steel maintains its properties during brazing and welding, even in the malleable raw state it features excellent mechanical characteristics, furtherly enhanced by the special Columbus cold-drawing process.

UTS=900MPa, Ys=800MPa, Ap5 =12%

Columbus Cromor

Columbus Cromor is a 25CrMo4 steel, seamed and cold drawn, butted to variable thicknesses using shaped mandrills. Cromor steel is produced starting from a calibrated tube which has already received two drawing processes, before being reinforced in all the possible variable thickness off ered by the range.

Mechanical characteristics:

UTS=750MPa, Ys=700MPa, Ap5 ≥ 12%